Arburg Trainees Win VDMA \"Carbon Busters\" Award

13.06.2022

• VDMA promotes climate protection: "next generation reduces emissions "

• First prize: Arburg trainees win 3,000 euros for reducing the carbon footprint of coffee machines

• Clearly calculated: the reusable cup concept can save ten tonnes of CO2 emissions per year

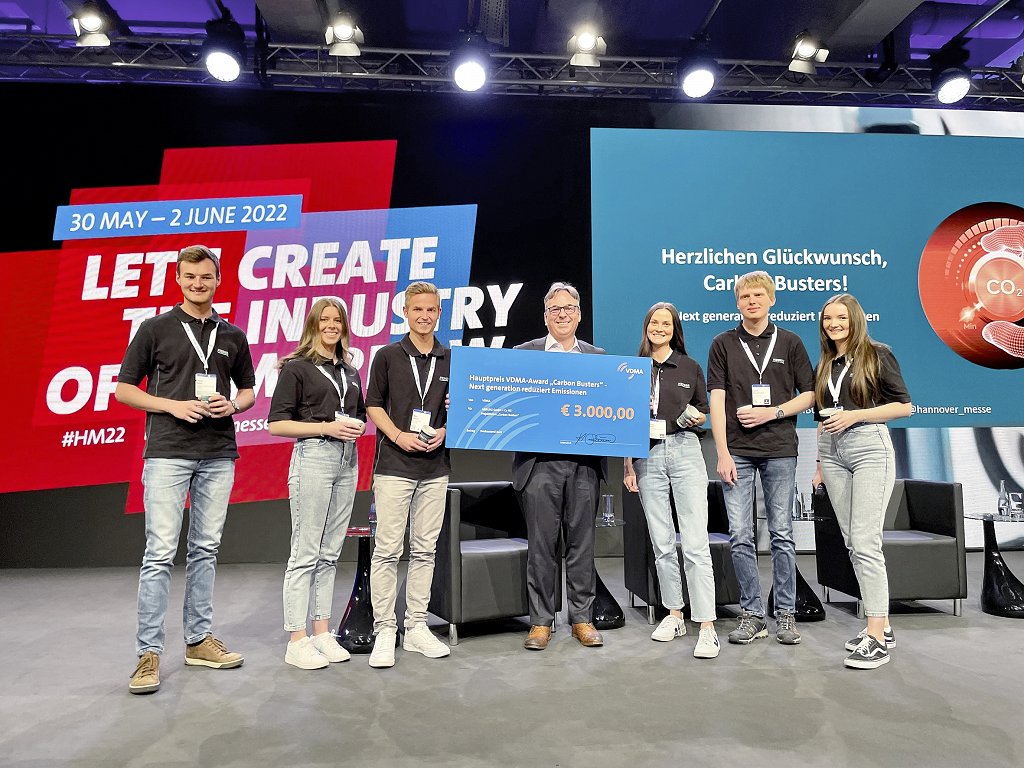

A team of six trainees from Arburg won the VDMA "Carbon Busters" Award on 30 May 2022. The competition, which offered a first prize of 3,000 euros, was held by the German Mechanical Engineering Industry Association (VDMA) as part of the Hannover Messe trade fair to honour the work of young climate protectors. The winning entry was an idea aimed at reducing the carbon footprint of coffee machines.

VDMA "Carbon Busters" Award: Hartmut Rauen (centre), Deputy Executive Director of the VDMA, presented the first prize of 3,000 euros to the team of six trainees from Arburg on 30 May 2022. From left: Tobias Helber, Denise Bohnet, Mika Hauser, Svenja Bross, Jannik Muenstermann and Sonja Fritz. Photo: Arburg

The jury’s decision was based on criteria including the team’s clearly formulated objectives, their comprehensive preparation of the project and their ability to put the idea into practice. "We are delighted that our concept for environmentally friendly coffee consumption has been so well received by the VDMA and, in particular, by Arburg," said Tobias Helber, a first-year IT trainee, on behalf of the project team. Tobias, Denise Bohnet, Svenja Bross, Sonja Fritz, Mika Hauser and Jannik Muenstermann invested around 250 hours in the concept and have already put some of their ideas into practice at the company headquarters in Lossburg.

Replacing single-use cups in coffee machines

The Lossburg site has 24 table top machines and 33 large coffee machines which dispensed a total of 900,000 hot drinks in 2019 – 85 per cent of which were in single-use plastic cups. The calculations carried out by the project team showed that manufacturing one single-use cup produces 14 grams of CO2. In contrast, washing ten crockery cups produces just 11.8 grams of CO2. A survey indicated that the vast majority of staff would be willing to switch to crockery cups or a reusable solution. Consequently, the team hung up posters to encourage all users to avoid single-use coffee cups and many employees have since switched to porcelain cups when using the table top machines.

Small change – big impact

Another of the team’s ideas was to connect the coffee machines to Arburg’s internal network via WiFi-enabled sockets so they can easily be switched off at weekends and during company holidays. The trainees calculated the power consumption of the coffee machines during use, on standby and when starting up. The results were as follows: if all 57 machines were switched off at weekends and during shutdown periods, this would save the equivalent of 6,058 hours’ worth of power a year, which corresponds to 0.138 tonnes of CO2 savings per year.

A more substantial goal that is yet to be implemented is to establish a reusable cup system for the large coffee machines. The team worked out that the solution with the lowest carbon footprint would be to use Arburg’s injection moulding machines to manufacture reusable cups that are compatible with the large coffee machines and to stock the machines with them. Used cups could be returned to a collection point and then cleaned in a separate dishwashing area on site at Arburg. If all of these measures are implemented, it will be possible to save around ten tonnes of CO2 emissions per year in future.

Further information about Arburg can be found at https://www.arburg.com/en/